Welding is an art; skill; trade; engineering discipline; and science.

From the Sydney Opera House and the Eiffel Tower, to local rail networks – welding is an important process that produces the building blocks for a safer and more advanced world.

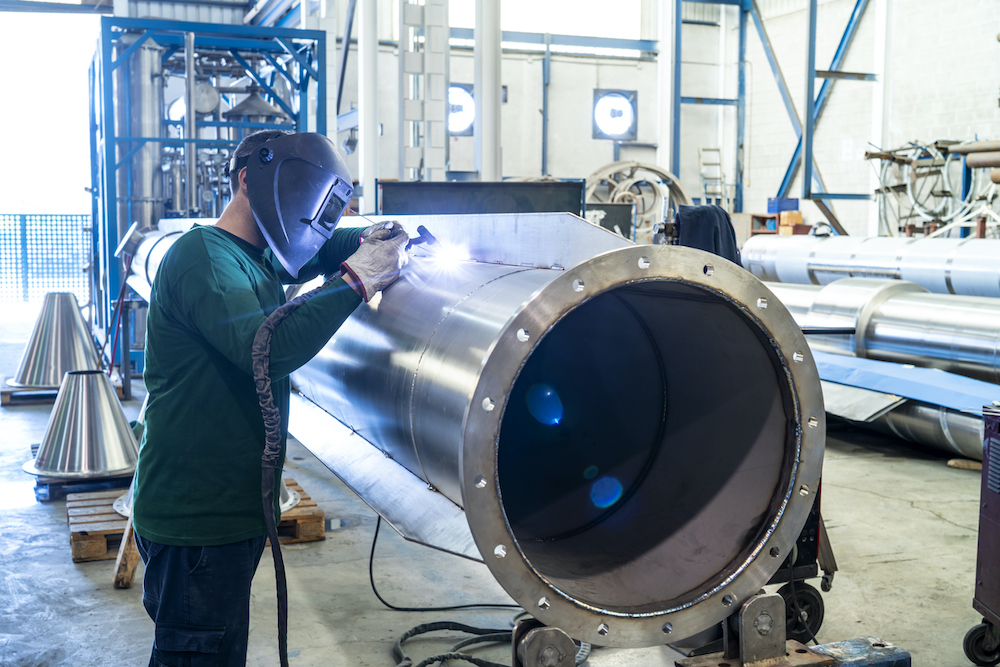

Welding involves fabricating single parts from two components, which are joined through a heating (and in most cases melting) and cooling process, allowing them to combine and form a solid joint. It is the most economic and effective method for permanently joining two metals – and the only way of joining two pieces to ensure that they serve as a single piece.

The aim of welding is to produce a single component with uniform mechanical properties such as strength and toughness across the joint.

While the welding process typically involves metals and thermoplastics, wood may also be welded if required. The whole process involves high heat exposure with complete precision, which can only be undertaken after meeting formal qualifications and gaining experience.

Parent Materials

Parent Materials

The two parts that are joined in the welding process are commonly referred to as ‘parent materials’. These are combined through ‘consumables’ or ‘filler materials’ which melt and solidify to form the welded joint.

Together, these materials may be referred to as: parent plates, pipe, filler wire, or consumable electrodes. They are often selected based on the mechanical properties of the parent materials, and form a homogenous weld, which means that the mechanical properties of the component are uniform throughout the joint.

Heterogeneous Welds

Heterogeneous Welds

In some instances, a heterogeneous weld may occur. This happens when a consumable, or filler has a unique composition, which leads to different mechanical properties between the welded joint and the parent materials.

Brazing and soldering are just two examples of heterogeneous welds.

The whole welding process is generally quite time consuming, as it demands complete accuracy and safety. Once complete, the welded joint may be referred to as a ‘weldment’.

Types of Joints

Types of Joints

There are many types of welded joints, selected based on configuration, accessibility and penetration. The most common are:

- Butt joint: a connection between two ends or edges to make an angle of around 180°

- T joint: a connection shaped like letter ‘T’, forming a 180° angle

- Corner joint: ends or edges of two parts make an angle of 30° to 135°

- Edge joint: an angle of 0° to 30° is created, including the joint region

- Cruciform joint: a cross-like configuration, that creates right angles

- Lap joint: two parts overlap and make an angle of 0° to 5°

Types of Welding

Types of Welding

Depending on what is required for a project, a wide range of welding processes may be utilised. The different types of welding include:

- Arc welding: a manual process that typically uses a filler material

- Friction welding: typically involves mechanical friction and does not use filler metals

- Electron beam welding: uses a high velocity beam of electrons to connect materials

- Laser welding: an automated process used for deep welds like thermoplastics

- Resistant welding: a fast welding process used in the automotive industry.

The process of welding is underpinned by Australian and International Standards, which ensure that all personnel are consistently operating under strict guidelines and meeting quality needs.

Safety is paramount to the industry. Typically, a welder will be seen wearing a mask with a screen protector for their face. Gloves and non-flammable clothing are also required to protect welders from the heat and sparks that occur during the practice.

Further Information

If you would like more information, please feel free to contact us.

Parent Materials

Parent Materials Heterogeneous Welds

Heterogeneous Welds Types of Joints

Types of Joints Types of Welding

Types of Welding