Many of the challenges impacting Australian welders, fabricators and manufacturers today are not new – high costs, rigid industrial relations laws and, of course, the enormous growth in competition from offshore manufacturers.

Throughout the 1950s and 1960s, Australian manufacturing was responsible for approximately 28% of the GDP, and 28% of all employment. Fast forward to today and, while manufacturing remains a vital part of the Australian economy, it is responsible for just 5% of the GDP, and only 5.4% of total employment.

This slow and painful death is due, in part, to market forces: an extended period of unfavourably high exchange rates; the rapid rise of China as ‘the world’s factory’; increasing wage costs; a lack of skilled workers; and increases in local energy and other input costs.

But it cannot all be blamed on market forces.

Successive state and federal governments continue to off-shore manufacturing work that the local industry is more than equipped to handle. This is also true of many of the big corporates.

The Offshore Problem

The Offshore Problem

Procurement professionals continue to chase the lowest purchase price rather than whole of life cost. While offshore manufacturing meets these needs, it does not maintain a high degree of quality control when compared to local manufacturing.

For example, the New South Wales Government ordered a fleet of inter-city trains from South Korea — at the bargain price of $2.3 billion. While the government had hoped the trains would prove 25 per cent cheaper than locally manufactured trains, the imported trains failed to fit the tracks. As a result, 20 stations required modifications, which expanded the total project cost to upwards of $3.9 billion — well above government estimates.

In fact, another area for Weld Australia’s advocacy is that every item sold in Australia complies with an Australian or internationally recognised Standard. This will ensure that Australian workers and the general population are kept safe.

Private business is equally quick to send — what should be — Australian jobs offshore. For example, BHP awarded more than 20,000 tonnes of structural steel work for its $4.7 billion South Flank project to an offshore manufacturer.

As a result, the steel fabrication industry has shrunk because of short-sighted procurement decisions. Not surprisingly, Australian fabrication companies have also gone broke and closed their doors, resulting in thousands of welders leaving the trade.

The Onshore Problem

The Onshore Problem

We need a commitment from state and federal governments to increased levels of local content for all procurement decisions. We need the big corporates to award local contracts to local companies.

The strength of the sovereign capability of Australia depends on Australians investing in Australia. It might be cheaper in the short-term to buy from Thailand, China, or South Korea, but all this does is weaken our economy.

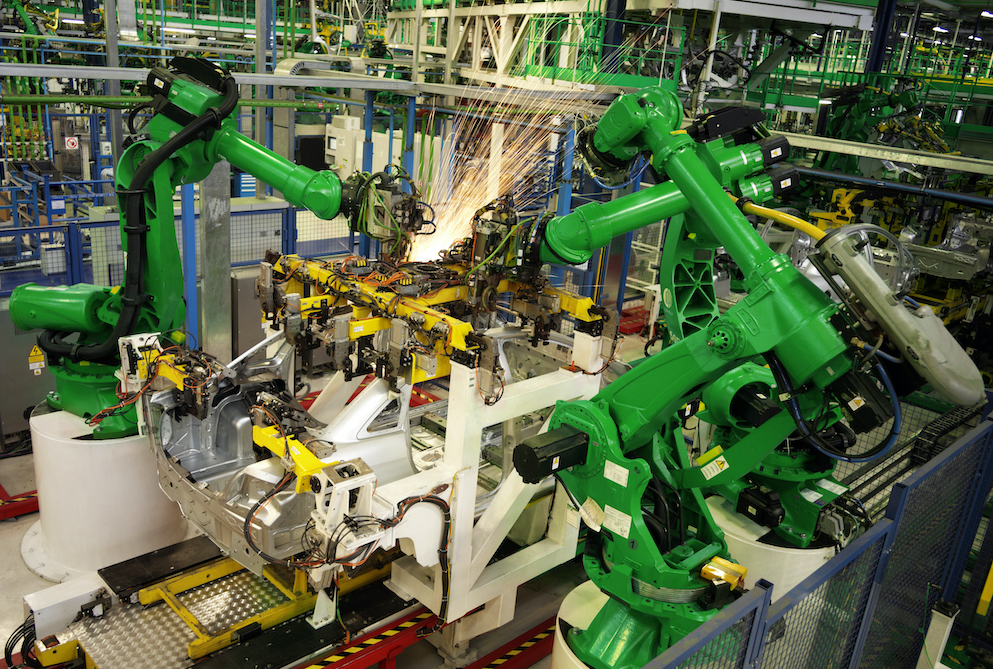

We need to invest in our economy. We need to bring home the manufacture of goods such as cars, rail infrastructure, and solar power equipment.

If we do this, local companies will then be in a position to invest in their own businesses, and to strengthen our manufacturing industry from within. Business innovation encourages the creation of strong and lasting new businesses and the creation of new and better jobs, which together support a move to higher living standards. Innovation investment by business is crucial to our ongoing prosperity.

To secure the future of Australian manufacturing and fabrication, we need determined action from our Governments, industry leaders, and the general public to put Australia first. We need to foster a sense of social responsibility.

We need Australians to support Australia.

The Offshore Problem

The Offshore Problem The Onshore Problem

The Onshore Problem