Safety is a critical consideration for any welding project. Welding is a safe occupation when proper precautions are taken.

But if safety measures are ignored, welders and members of the general public face a range of hazards that can be potentially dangerous. These hazards include electric shock and electrocution through to structural failure, or even death.

In an Australian context, overall adherence to safety regulations and relevant Australian Standards is sufficient, but there are also some significant gaps in the compliance framework that have long term safety implications. Weld Australia advocates for a wide range of safety requirements and initiatives in the welding and fabrication sector, including:

• Workplace health and safety (welding fumes and electrical safety)

• Non-compliant welding equipment (electrical safety)

• Integrity of welded structures and pressure vessels

Together, these safety issues have the potential to cause very real — and very serious —accidents and injuries, as well as fatalities.

Fume Minimisation

Fume Minimisation

In recent times, concerns around airborne contaminants generated by the welding process have been raised by industry, particularly following the reclassification of welding fume from Group 2B Possibly carcinogenic to humans to Group 1A Carcinogenic to humans by the International Agency for Research on Cancer (IARC) in March 2017. This reclassification was subsequently published in the IARC’s Monograph 118 in July 2018.

In January 2024, Safe Work Australia announced that Work Health and Safety Ministers have agreed to an immediate reduction in the workplace exposure standard for welding fumes, from an 8-hour time weighted average (TWA) of 5 mg/m3 to 1 mg/m3.

As the exposure standard for welding fumes has been reduced, all necessary controls must be implemented to meet this higher standard.

For further information, see our Welding Fumes resources.

Welding Safety Council

Weld Australia has established the Welding Safety Council to advocate for strong safety requirements and risk minimisation in the sector. The council provides a forum for industry and legislative safety authorities to discuss issues and work collaboratively to identify solutions.

Weld Australia seeks to use this initiative to eliminate the loss of life or injury attributable to welding practices – in an industry that is generally safe. The mission of the Welding Safety Council is to establish and maintain the infrastructure required to identify and analyse welding risk. It engages its stakeholders in formulating mitigation strategies and uses its influence to execute these strategies.

Through the help of key government stakeholders, statutory bodies and industry, the Welding Safety Council is a powerful body for the Australian welding industry to take a significant step forward in protecting both the general public and welders.

Welding Equipment

Welding Equipment

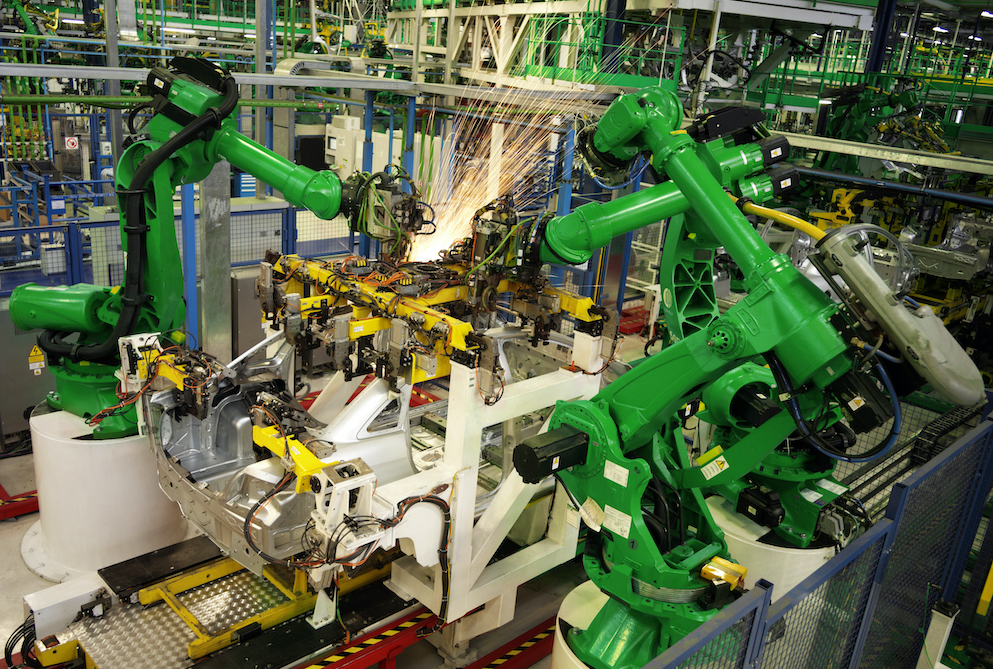

Technology has come a long way over the past few decades. Today, welding machines come packed with more power than ever and top brands continue to push the limits with new generations of equipment. The performance of modern day machines are constantly reaching new heights and as more brands enter the market, this trend will only continue into the future.

However, the increased performance is a double-edged sword in some machines. Many brands will supply leads and plugs for a machine that do not hold the power required to run at peak power. Incorrect fittings can be dangerous, and a welder’s inability to maintain high currents can become a potential safety risk.

Fume Minimisation

Fume Minimisation Welding Equipment

Welding Equipment