Industry, Schools and Governments Must Work Together to Foster STEM Career Pathways

Geoff Crittenden | CEO, Weld Australia

Weld Australia is calling on industry, schools and governments to work together to develop and deliver STEM programs that engage, excite and attract students.

Australia needs a vibrant national STEM skills program that illuminates the opportunities available in careers like welding and manufacturing for kids and parents alike.

Australia needs a vibrant national STEM skills program that illuminates the opportunities available in careers like welding and manufacturing for kids and parents alike.

Apprenticeships focused on STEM skills were once considered to be the foundation of gainful employment in Australia, with university studies out of reach for many until the 1980s. Since then, apprenticeships have steadily declined in popularity while university intakes have increased.

But the employment market is becoming increasingly difficult for university graduates, compared to a national shortage of skilled labourers across the welding, fabrication, construction and manufacturing sectors. Workforce capability and availability is a growing challenge for the welding and fabrication sector.

Welders are more in demand than ever with several large-scale, high-value projects on the horizon, from the Federal Government’s $90 billion Naval Shipbuilding Program, through to major infrastructure projects such as the $12 billion Sydney Metro project, and the $5 billion Melbourne Airport Rail Link.

And yet, the number of welding trade workers in Australia dropped by 8 per cent in the course of just five years; from 75,800 in 2014 to 69,600 in 2019. In addition, completion rates of welding apprenticeships, including a Certificate III in Engineering (Fabrication Trade), continue to fall by as much as 23 per cent annually.

Apprentices are an important asset to securing Australia’s local manufacturing sector, generating growth, and stimulating the economy. Australia requires a significant increase in skilled, qualified tradespeople—equipped with in-depth STEM skills—on major projects, and in industries as diverse as defence, shipbuilding, aerospace, infrastructure, manufacturing, mining and resources.

The Skills of the Future

STEM skills are crucial to the changing nature of work. Digital technology is now a part of our everyday lives, and is impacting the world of work in ways never experienced before.

STEM skills are crucial to the changing nature of work. Digital technology is now a part of our everyday lives, and is impacting the world of work in ways never experienced before.

According to the Federal Government’s Department of Education, Skills and Employment, it’s predicted that future workers will spend more than twice as much time on job tasks requiring science, maths and critical thinking than today. It’s vital that Australia keeps pace with technological change to advance its economy and prosperity.

Attracting and retaining younger talent while they are at high school, and then through engaging, well-funded training and apprenticeships is critical to combatting the severe skills shortage.

Our young people need to acquire complex, high order technical knowledge and skills. They need robust, deep and transferrable qualifications that provide a strong base for life-long learning and skill development.

Kids need STEM skills.

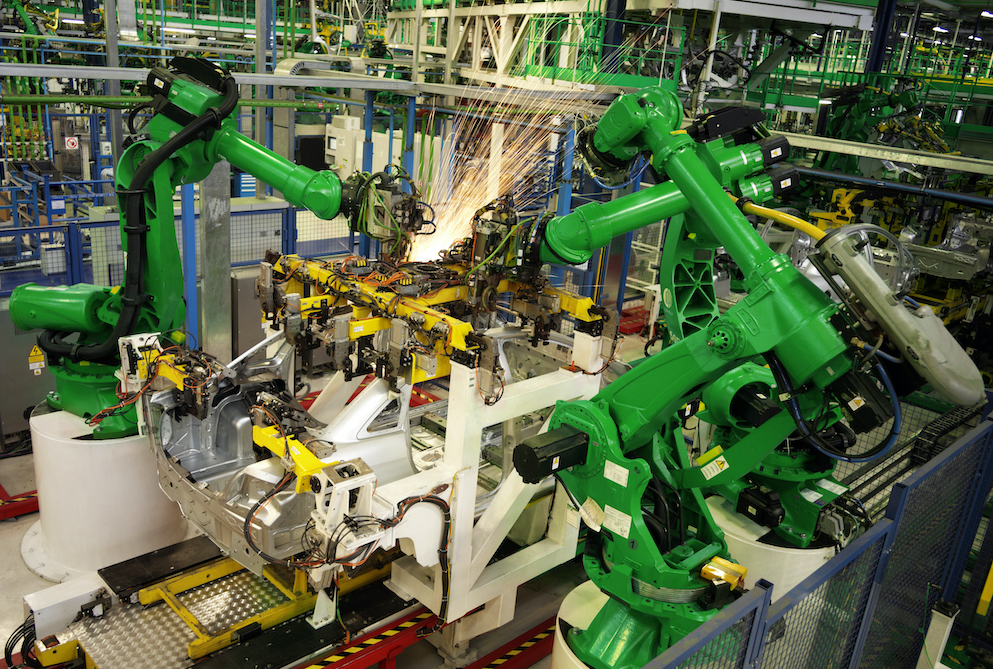

We need a vibrant STEM program implemented across schools nationally so that children and parents alike understand the opportunities available—the future of employment in industries like welding is not hard, dirty work carried out in a dark workshop, it’s focused on IT and programming skills, using robots and co-bots, and implementing Industry 4.0 concepts.

Australia is Not Keeping Pace with the Need for STEM Skills

There are many reasons to be concerned about Australia’s STEM activity. The number of school students studying STEM in later secondary (Year 11 and 12) has flat-lined at around 10% or less.

There are many reasons to be concerned about Australia’s STEM activity. The number of school students studying STEM in later secondary (Year 11 and 12) has flat-lined at around 10% or less.

Unfortunately, the latest OECD Program for International Student Assessment (PISA) results show a long-term decline in maths and science skills for Australian students. In 2018, Australian 15 year-olds, performed more than a year below those in 2003 in maths, and a year below in science when compared to the 2006 results.

It should therefore be no surprise that in the last OECD study of graduates by subject Australia was placed 36th for Engineering and 14th for Arts; despite there being a demand for the former and a surplus of the latter. Australia is slipping down the international ranking tables as other countries improve. In 2003, four countries or economies significantly outperformed Australia in PISA mathematics. In 2018, 23 did.

The same outcome is reflected in the VET sector, where there has been a long-term decline in registrations and completions of nationally recognised engineering trade courses.

The Australian Council for Education Research (ACER) review published in 2019 notes the challenges for STEM education at school level have not been met; student engagement and performance in STEM have been declining and Australia does not have the supply of qualified teachers to improve learning.

Furthermore, it is widely recognised that careers advice and student exposure to work opportunities is poor, particularly in STEM based industries. In its 2018 review, the (Victorian) Education Department found careers education started too late in government schools, varied in quantity and quality, and did not provide enough meaningful work experience.

Australian students, their parents and their teachers simply don’t understand the importance of STEM, or STEM career opportunities, until it’s too late.

Innovative STEM Programs in High Schools

One way to combat this lack of understanding around STEM career opportunities is through innovative STEM programs in high schools.

One way to combat this lack of understanding around STEM career opportunities is through innovative STEM programs in high schools.

In June 2020, the New South Wales (NSW) Department of Education and Training (DET) commenced a pilot program to teach welding to students in Years 10 to 12 studying Manufacturing and Engineering, and Industrial Technology. The program utilised cutting-edge training techniques, including the use of 32 augmented reality welding simulators and innovative teacher training delivered by Weld Australia. Based on the success of the pilot program, NSW DET ordered a further 20 simulators to be rolled out across another 10 high schools in regional NSW.

This STEM program substantially boosted the number of recruits into the trades broadly, and welding in particular. However, the greatest benefit was the creation of a long term solution to the skills shortage by exposing all students to the opportunities offered by a career in welding.

Perception and lack of awareness can create barriers, preventing many young adults from engaging in careers in manufacturing and the trades, and reaching their full potential. STEM opportunities in the manufacturing sector are clean and technically sophisticated, requiring a range of advanced skill sets, as well as traditional skills. This new approach surprised and re-engaged students, providing hope for their future.

The Way Forward

To resolve the growing lack of STEM skills, Australia has adopted a ‘push’ approach by focussing on school based STEM programs like that implemented by the NSW DET.

To resolve the growing lack of STEM skills, Australia has adopted a ‘push’ approach by focussing on school based STEM programs like that implemented by the NSW DET.

There is no question that STEM education and careers advice must be improved. But industry cannot continue to rely on Government to solve the problem. There also needs to be a ‘pull’ strategy that engages students through close collaboration between schools and companies.

Weld Australia member, Precision Metal Group (PMG) is strong advocate for this type of ‘pull’ strategy. In 2020, PMG began partnering with Parramatta Marist High School to develop a metals and welding program. The program is fostering STEM skills so that students are better prepared to contribute to Australia’s rapidly growing advanced fabrication and manufacturing industries.

The shared vision is to have more and more students exposed to the industry, and certified as armoured vehicle welders before they graduate from Parramatta Marist, providing them with pathways supported by a skill set in demand by the Australian Defence Force. To begin, Year 10 iSTEM students rotate through fortnightly two hour welding core skills workshops, while self-nominated students undertake intensive welding training at PMG’s facility in Wetherill Park.

“Identifying and developing skills should start in school. Students of all ages need to be excited by the opportunities available in welding, and in trades more broadly. Industry and schools need to work together to develop and deliver programs which engage, excite and attract students.”