WELDED STRUCTURES

RESIDUAL STRESS & DISTORTION CONTROL;

FATIGUE DESIGN

LIVE WEBINAR or BRISBANE | 4 & 5 JUNE 2025

Expand your proficiency in the engineering and design of welded structures.

Grow your technical skills on residual stresses and distortions.

Facilitated by USA expert Pingsha Dong, this two day course will cover the fundamentals that every engineer should know when designing welded components. From weld in-situ strength, residual stresses, and geometric discontinuities, every aspect plays a different role in contributing to resultant joint strength, and fatigue resistance. Implications on metallic additively manufactured (AM) parts will also be discussed.

With plenty of opportunities for questions, this course can help attendees mitigate the detrimental effects of welding defects, reducing inefficiencies and costs, and improving project schedules and productivity.

WHO SHOULD ATTEND?

Designers, structural engineers, consultant engineers, mechanical engineers, welding and production engineers, maintenance and quality control engineers, as well as researchers. Attendees are encourages to bring along their design problems to contribute to discussions and local case studies.

WHAT INDUSTRIES IS THE COURSE RELEVANT TO?

The course will be especially relevant to all professionals in automotive, aerospace, steel construction, steel bridge design, power generation, naval and shipbuilding, offshore construction, pipeline and other industries that apply welding.

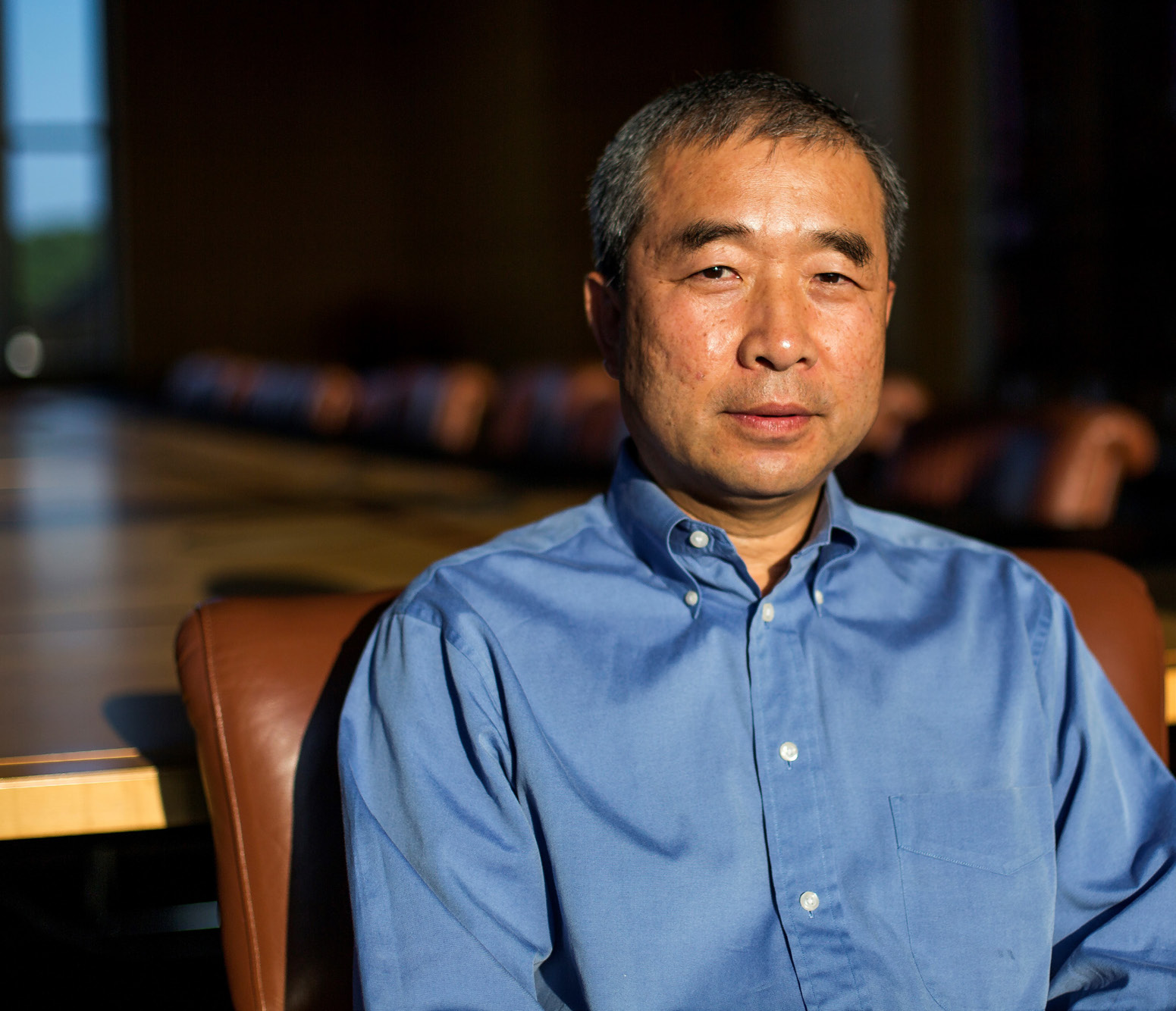

About the Presenter: Professor Pingsha Dong

Professor Pingsha Dong of the University of Michigan, is the inventor of the mesh-insensitive structural stress method (also referred to as the Master S-N Curve Method) adopted by the 2007 ASME Div 2 and API 579/ASME FFS-1 Codes and Standards mandated by over 50 countries worldwide. Over the past 20 years, Professor Dong has taught courses in fatigue design, fracture control, residual stress and distortion control in over a dozen countries around the globe.

Professor Pingsha Dong of the University of Michigan, is the inventor of the mesh-insensitive structural stress method (also referred to as the Master S-N Curve Method) adopted by the 2007 ASME Div 2 and API 579/ASME FFS-1 Codes and Standards mandated by over 50 countries worldwide. Over the past 20 years, Professor Dong has taught courses in fatigue design, fracture control, residual stress and distortion control in over a dozen countries around the globe.

Professor Dong has published more than 260 peer-reviewed papers in archive journals and major conference proceedings, including over 20 plenary and keynote lectures at major international conferences. He has received numerous prestigious national and international awards, including AWS Comfort Adams Lecture Award (2019), SNAME Helmer L. Hann Awards (both in 2012 and 2007), IIW Evgeny Paton Prize (2008), R&D Magazine’s R&D 100 Award (2006), TIME Magazine’s Math Innovator (2005), Aviation Week and Space Technology’s Aerospace Laurels Award (2004), SAE Henry Ford Award (2003), AWS R.D. Thomas Award, and ASME G.E.O Widera Literature Award (2002), among many others. He is also a Fellow of ASME, AWS and IIW.

COURSE CONTENT

Day One: Residual stress and distortion control: considerations from design to construction

- Simple descriptions on how residual stress is generated in manufacturing

- How are distortions related to residual stress?

- How to quantify the importance of residual stresses to structural integrity

- Typical distortion types and control methods:

- by design (such as weld positioning, weld type, and so on)

- by process (such as sequencing, support, and so on)

- Real-word case studies:

- shipbuilding

- pressure equipment

- aerospace

- automotive

- Closure and Q&A

Day Two: Fatigue design methods for welded structures: what works, what don’t, and why?

- Unique fatigue behaviors in welded structures

- Traditional fatigue design and life evaluation methods

- Nominal stress methods

- Hot spot stress methods

- Notch stress methods

- Applicability for today’s needs and real-world examples

- Mesh-insensitive structural stress method adopted ASME B&PV Code

- Basis and calculation procedure

- Master S-N (E-N) curve definition and usage

- Relationship to nominal stress method

- Demonstration examples

- Fatigue resistant joint design and examples

- Joint positioning

- Joint type selection

- Joint detailing

- Closure and Q&A

COURSE DETAILS

- Date: 4 and 5 June 2025

- Location: Join online via Live Webinar, or attend in-person in Brisbane

- Venue: The Amora Hotel, 200 Creek Street, Brisbane

- Registration first day: 8:00am

- Course time: 8:30am – 5:00pm

- Morning tea, lunch and afternoon tea provided

COST

Membership rates apply to all Weld Australia members.

- Members $3,410

- Non members $3,718

- Live Webinar: Members $3,110

- Live Webinar: Non members $3,418

Payment is required at the time of booking. Cancelation four weeks prior to the start date will not be refunded.

Please note: in order for the course to go ahead, minimum attendee numbers must be reached.